El Hidrógeno Verde

Desde el año 2015 , en ARPA hemos trabajado en el desarrollo de soluciones para las instalaciones de Hidrógeno verde.

- Producción

- Almacenamiento

- Transporte

Somos una entidad emprendedora , que creemos firmemente que hacer un mundo mejor es posible.

Desde la industrial podemos colaborar para que este mundo sea sostenible, pero debemos comenzar ya.

Hidrógeno Verde es parte de esa solución para cambiar el modelo energético y para ello una nueva industria , en la que ARPA ya está, es necesaria.

En el año 2018, ARPA invirtió en una instalación de 112kW pico, para poder hacer la transición energética en la propia empresa. Fuimos capaces de que durante los 220 días laborables, alrededor del 80% de ellos se pudiera a la vez que consumir, generar Hidrógeno Verde en nuestras propias instalaciones.

Ya en el año 2019 invertimos en el desarrollo de un equipo modular , para generar Hidrógeno Verde alimentado por excedentes de PV, a su vez también desarrollamos un módulo dispensador para poder aprovechar esos excedentes en forma de H2 verde para nuestra propia flota.

Uno de los grandes hitos fue en el año 2020, año en el que iniciamos el proyecto ZEM, un proyecto que hemos llevado a cabo junto con el CUDZ y es estudio de arquitectura B+Haus, el primer módulo habitacional Pasivhaus con backup de hidrógeno. Con la colaboración de la Fundación Hidrógeno, nuestro proyecto fue financiado con fondos europeos pertenecientes al programa LIFE. En estos momentos este proyecto está siendo testado en el campo de maniobras de San Gregorio en Zaragoza, a finales del año 2023 partirá para ser instalado en la base militar Gabriel de Castilla en la Antártida.

Otra fecha significativa es el año 2022, fecha en la que iniciamos una entusiasta aventura junto con el Grupo Zoilo Ríos. Un proyecto que se centra en la divulgación, conocimiento y popularización del H2 verde centrado en la movilidad. Esta aventura se llama SHIE. Una nueva entidad en la que nos centramos en motivar a la industria de la movilidad, acompañándolos en la transición hacia el H2 verde. Este acompañamiento lo hacemos a través del desarrollo de infraestructuras para la producción y dispensación del mismo. Nuestras infraestructuras son de fácil instalación, fácil manejo y con costes contenidos.

Desde SHIE, ofrecemos consultoría, asistencia técnica y financiera , y por supuesto un proceso de mentorización en este proceso de transición.

ARPA , he fijado firmes alianzas, ya en el año 2019 pasamos a formar parte del ecosistema de la industria del H2 verde europea. Fruto de esta colaboración con otros fabricantes europeos de componentes relacionados con la tecnología del hidrógeno, alcanzamos acuerdos con entidades como Enapter. Esa relación con entidades se vio fortalecida en septiembre del año 2022, con el acuerdo de alianzas con entidades como, SERA, WEH, TOYOTA. Todas ellas entidades de gran prestigio a nivel internacional, que han confiado en ARPA como una entidad referente a nivel internacional, en ingeniería de diseño y fabricación de infraestructuras para la producción, almacenaje, comprensión y dispensación.

La investigación y desarrollo, es clave en nuestra entidad, es por ello que hemos sido adjudicatarios de módulos de generación de hidrogeno para la Universidad de Barcelona, también hemos colaborado de forma activa en otros proyectos como son CSIC, ITAinnova, etc…La Agencia Europea de la defensa también ha confiado en nosotros , y en el año 2022 nos hizo adjudicatarios de los proyectos Nomad e Indy, proyectos que buscan desarrollar soluciones robustas de abastecimiento energético basados en energías renovables e H2 verde.

Otro proyecto importante es la colaboración con CAF, en la primera dispensación de un tren de H2 verde en España y con Repsol en la prueba piloto de un autobús urbano en la Coruña.

Nuestro próximo proyecto es realizar junto con la colaboración del Grupo Zoilo Rios, en la instalación de la primera hidrogenera tanto a 350 bar como 700 bar, abierta al público en España. Un proyecto que nos pone en la vanguardia del desarrollo de proyectos en Hidrogeno verde.

Nuestra entidad está comprometida con nuestro planeta ,apostando y creyendo que una industria sostenible es posible.

MOTORTECH Madrid Abril 2022

EHEC Madrid Mayo 2022

H2 EUROPE-HANNOVER Mayo 2022

H2 CONGRESO RIOJA Junio 2022

Ver más

HIDROGENERA 30 Kg H2@500

Firma Nomad / Indy

Demo Dispensados:

CarretillaH2 Toyota

TrenH2 CAF

BusH2 Caetano REPSOL CORUÑA

CarretillaH2 Linde

Ver más

Ver más

Compresión H2@470 bar

Dispensados Toyota Mirai

Proyecto ZEM, Base Antártica Zero Emisiones PasivHaus Backup Energia H2

Ver más

Ver más

Any question?

Advantages

of our system

- Simple and modular installation (adaptable to demand)

- No need for on-site generation (feeding through bottles)

- Minimum environmental impact and 100% renewable solution

- Contained costs

- Reliable and easy service

- High flow rates and minimum refueling times

- Low consumption with high performance equipment

- Modular and scalable

- Minimum maintenance

- Silent

HYDROGEN

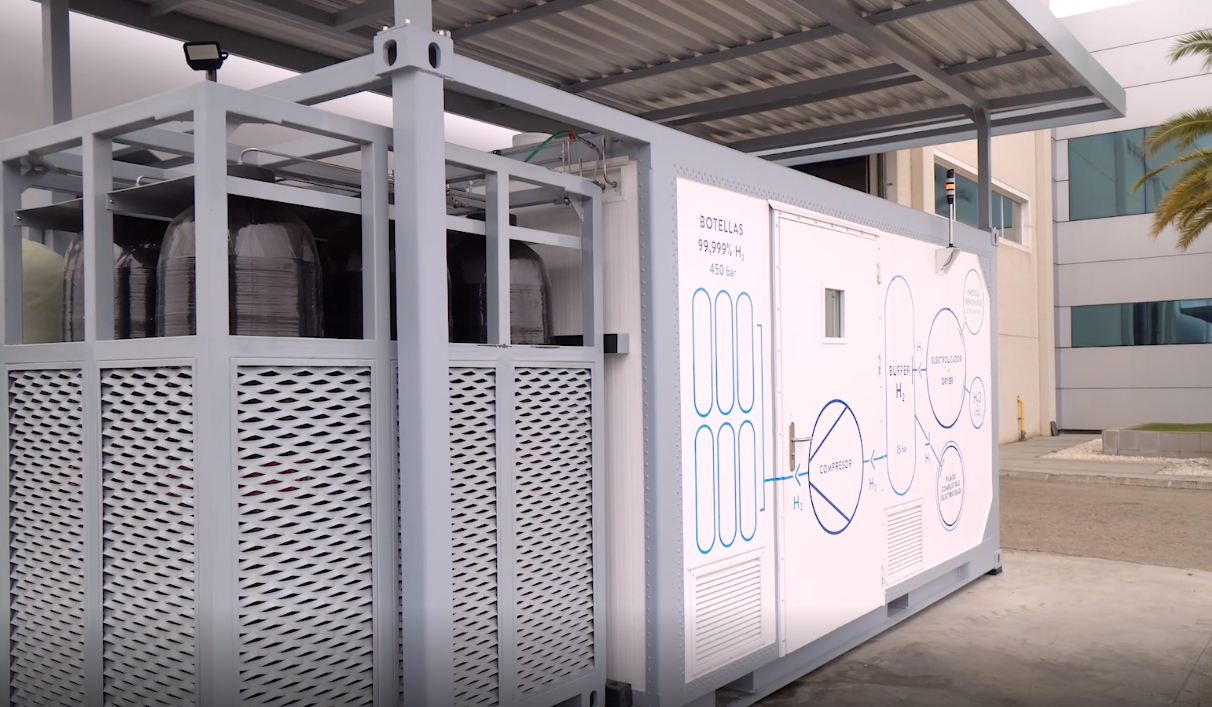

MODULAR HYDROGEN STATIONS

Different models with generation capacities that can range from 5 KgH2/Day to 100 KgH2/Day. Formats in 20' or 40' containers.

Specs

- Purity of generated hydrogen of 5.0

- High performance multistage membrane electrolyzer

- Compression stage included up to 500 bar

- Storage system low to 60 and high to 500

- Key hand solution with BOP implemented

- Remote plant monitoring system.

HYDROGEN

DISPENSERS

350 bar dispensing standard. Dispensing flow rate of 1.8 kg H2/min. Possibility of double branch dispensers (dispensing 700 bar) and flow rate of up to 3.2 kgH2/min

Specs

- Portable format.

- Remote monitoring of the dispenser.

- Bypass for ramp connections and other reservoirs.

- Type IV hydrogen cylinders, TPED@500.

- Accommodation for bottle cage, up to 45 kg H2.

- Turn-key solution.

- Application: Trucks, buses, trains, ships and passenger cars.

HYDROGEN

ZEM PROJECT

It is a LIFE program of PASSIVE HOUSE life bases with 100% energy efficiency. IN-SITU generation of green hydrogen.

HYDROGEN

CURRENT MANUFACTURING PROYECTS

Hydrogen generation station of 35 Kg for service stations. Dispensers. H2 generators and battery groups: Seasonal applications, universities and laboratories.